What is Kitenge?

Kitenge is traditionally made using a batik technique. Manufacturing is a complex and time-consuming production process. It is highly regarded as a manual and labor intensive art form.

preparation

The locally grown cotton (mostly from Ethiopia or Tanzania) is spun into yarn and woven into cloth. Since this is still rather grey, it must be bleached white and cleaned. At the end, the cloth is reinforced and stretched to the desired width.

design and colouring

In order to design the fabrics, black and white printing forms are usually designed on the computer with the help of software, which are then enriched with different colors.

This pattern is now printed on both sides with a wax. The wax used is a natural product obtained from pine resin. Because of the wax print, Kitenge is also called wax print fabric.

In an indigo dye bath, the exposed parts of the fabric are dyed and the resin-coated parts are made resistant.

The wax is then broken up with special machines to obtain, for example, marbling or bubbles, this is called the crackle effect.

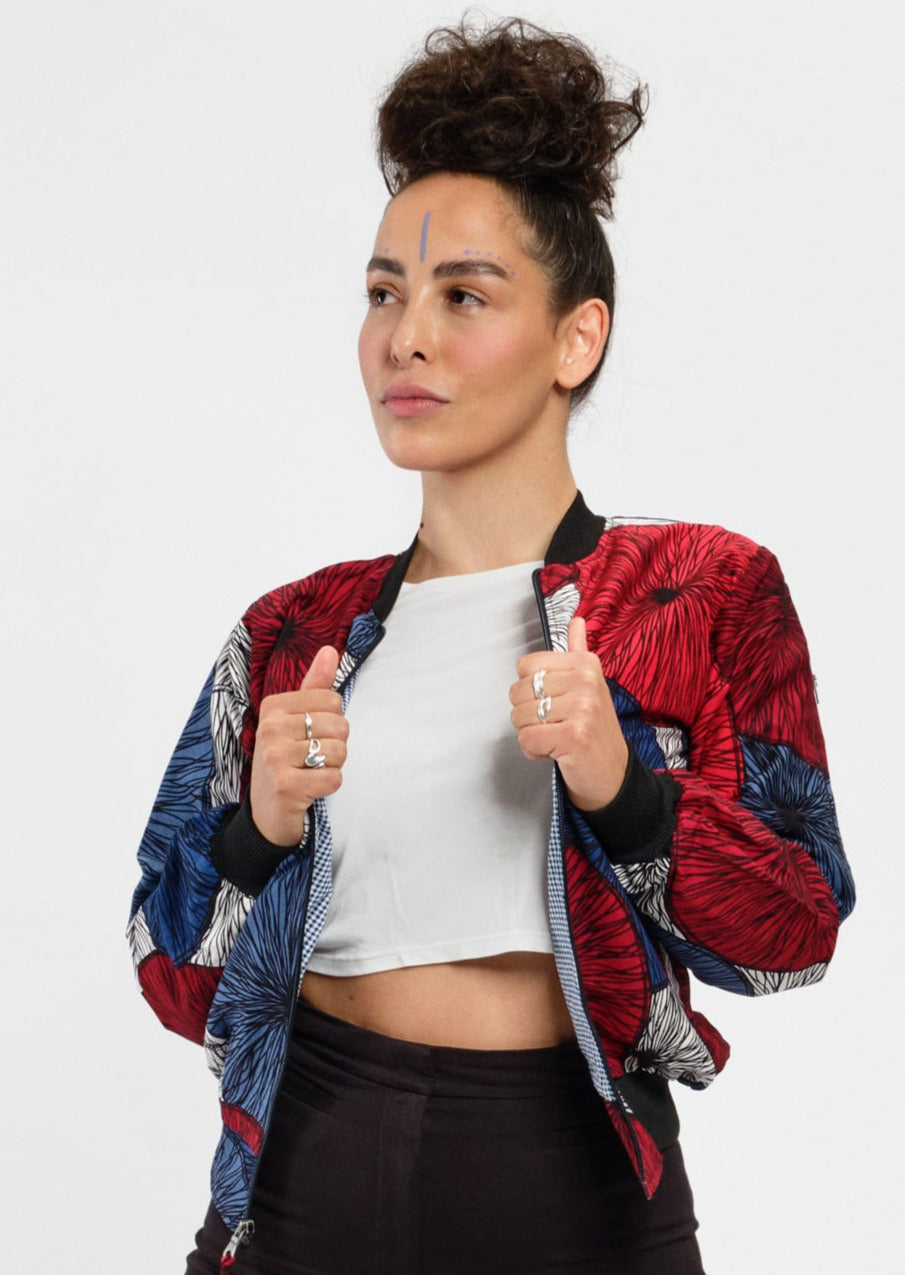

Kitenge and Kangas

coloring

Before or after removing the wax from the fabric, large industrial printing machines are used to add solid color to the design.

Sometimes part of the design is hand carved onto a block of wood and applied to the fabric (known as block printing).

This dyeing process is key to making kitenge fabrics.

washing and finishing

The cloth is then laundered to remove any small wax residue and excess dye to ensure colorfastness standards are met.

Due to the naturalness of the wax printing process, it is impossible to make every piece of fabric look exactly the same, every piece is unique.

In addition, since our tailors hand-cut the fabric from which our garments are made, the print positioning is different on each piece. Each jacket is very special and unique!